$0.00

Engine Emissions – How Emission Standards Affect Turbocharging?

Emissions from Diesel engines are a never-ending concern to all Diesel engine vehicle owners. For years now, we have been told that Diesel engines are harming the environment way more than other engines. Moreover, the latest Euro 6 regulations brought a lot stricter emission regulations which adds to the dismay of all Diesel engine enthusiasts. A well-known leader in the automotive industry has also been involved. Volkswagen admittedly ‘tweaked’ the emission control systems of nearly half a million cars sold in the US to pass the NOx emission regulations. Of course, the models were in fact not fit for the required emission standards.

The issues with testing engine emissions in Diesel engines have been known for a while and many have been trying to implement new technologies to remedy the situation. For instance, some improvements may enhance the efficiency capabilities of the petrol engine making it similar to the diesel engines. How does that relate to turbocharging? Let us look closer at the turbochargers and the engine emissions in diesel engines.

Engine Emission Standards Explained

To understand the importance of turbocharging, let us start by examining the standards emissions from diesel engines are subjected to.

The history of restrictions dates back to 1992 when a switch to unleaded petrol was imposed to reduce the mission of CO. This was also accompanied by the Euro 1 requirement of the installation of catalytic converters. The more time has passed, the more the standards were tightened. They were also adjusted to the different engine types (petrol vs diesel). The real diesel cars scrutiny started with Euro 4 and Euro 5 (2005/2009) reduction of particulate matter and oxides of nitrogen (NOx).

Further steps included tightening the reduction of NOx emissions from diesel engines. Furthermore, it was time to introduce uniform standards of engine emissions to be met by both types of engines. However daunting and difficult the introduced standards might have been, they turned out to be a success, as the PM emission levels decreased by 96% reduction and NOx levels were reduced by 87%. How exactly did that happen? Thanks to the development of special technologies that helped to reduce emissions from diesel engines.

Technologies that helped to reduce emissions from diesel engines

The first improvement in emissions came with the introduction of catalytic converters. Their role significantly reduced the CO and HC particulates that were a product of the engine combustion process. Their conversion of CO and HC to Carbon Dioxide and water was treated as a breakthrough and resulted in the permanent change to diesel engine construction in the form of a Diesel Particulate Filter. Thanks to that, all new diesel engines had preventive mechanisms effectively disabling soot and other harmful substances from leaving the exhaust and entering the atmosphere. The result was a reduction by an astounding 85%!

Another piece of technology that was built to help with the emissions from diesel engines was the Selective Catalytic Reduction system. They focused on the reduction of NOx emissions by injecting the Urea into the exhaust post-combustion. As a result of the ammonia reaction with harmful NOx the end product we receive is Nitrogen and H20. It was thought to be a ground-breaking development. However, it failed to deliver the expected results. Unfortunately, the lab results were not corresponding to the emissions and products that occurred in real-life driving conditions. As a result, the emission levels imposed by the restrictions could not be met. This prompted Volkswagen to intervene with the tests which resulted in a worldwide scandal.

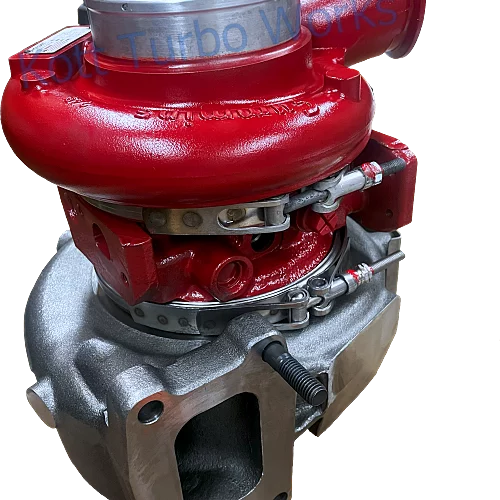

How Emission Standards Affect Turbocharging

Any changes made to the vehicle engine correlate with its components. Not all of them are beneficial. Therefore, there is much to be said about the turbochargers’ performance as a result of the introduction of the two above-mentioned technologies. As you can tell, the Diesel Particulate Filters were rather a success when it comes to the reduction in engine emissions. Unfortunately, this system greatly contributes to turbocharger failures. Such filters impose restrictions on the gas flow, which subsequently negatively affects the vehicle’s power output. In short, the turbocharger has to increase the operation which in turn hinders the fuel efficiency. Furthermore, if the filter gets blocked, it reduces the fuel efficiency even more, which ends up damaging the turbocharger and the engine itself. There is a great correlation between the blocked Diesel Particulate Filter (DPF) and the need for the turbocharger replacement. In such a case, the driver must not only repair the blocked filter but also the turbocharger.

The Problems with Engine Emissions Improvements

Having to replace the filter and the turbocharger is often a cost that the drivers are not prepared to incur. They either face the choice between writing off their vehicles (not uncommon!) and trying to cut unexpected costs. They very often fall victim to dishonest suppliers of low-quality aftermarket DPFs which further deteriorate the turbochargers' condition. To make matters worse, it is not uncommon to have the DPF removed from the vehicle and come back to square one with the production of the harmful substances that the Governments so vividly want to reduce.

What is the remedy? Purchasing your aftermarket components from a trusted supplier. Make sure that both your DPF and your turbocharger are of high quality by purchasing them from suppliers that are skillful experts in the field.

Turbokott is at your disposal not only in all turbocharger-related matters but also in all questions you might have regarding aftermarket engine parts. Get in touch to avoid costly repairs and downtime.

Featured Products

View All

Need Help?