$0.00

The Evolution of Turbocharger Technology

Turbochargers have come a long way since their inception, evolving from simple mechanical boosters to sophisticated, high-tech marvels that enhance engine performance and efficiency. In this article, we will explore the fascinating journey of turbocharger technology, highlighting key milestones and innovations that have shaped its evolution.

Imagine driving a truck up a steep hill with a heavy load. Without the help of turbocharger technology, your engine would struggle to maintain power and efficiency. Turbochargers have revolutionized the way engines perform, providing a significant boost to power and efficiency. But how did we get here? Let’s dive into the history of turbochargers and explore the advancements in turbo technology that have brought us to the present day.

Early Beginnings: The Birth of Turbochargers

The Concept of Forced Induction

The concept of forced induction, where air is compressed and forced into the engine to increase power, dates back to the late 19th century. Early pioneers like Gottlieb Daimler and Rudolf Diesel experimented with ways to enhance engine performance. However, it wasn't until the early 20th century that the first practical turbocharger was developed.

First Applications in Aviation

The initial use of turbochargers in aviation during World War I and II marked a significant milestone in the history of turbochargers. Engineers realized that turbochargers could help aircraft engines maintain power at high altitudes where the air is thinner. This innovation provided a crucial advantage in aerial combat, allowing planes to fly higher and faster.

Transition to Automotive Use

Early Automotive Turbochargers

After proving their worth in aviation, turbochargers began to make their way into the automotive industry. In the 1960s and 1970s, manufacturers like General Motors and BMW started experimenting with turbocharged engines in their cars. The 1962 Oldsmobile Jetfire and the 1973 BMW 2002 Turbo were among the first production cars to feature turbochargers.

Challenges and Limitations

Early automotive turbochargers faced several challenges, including reliability issues and turbo lag—a delay in power delivery due to the time it takes for the turbocharger to spool up. Despite these limitations, the potential for increased power and efficiency kept engineers and manufacturers invested in the technology.

Technological Advancements and Innovations

Introduction of Intercoolers

One of the significant advancements in turbo technology was the introduction of intercoolers. Intercoolers cool the compressed air from the turbocharger before it enters the engine, increasing its density and improving combustion efficiency. This innovation helped reduce engine temperatures and improve overall performance.

Variable Geometry Turbochargers (VGT)

The development of Variable Geometry Turbochargers (VGT) was another critical milestone in the turbocharger innovation timeline. VGTs feature adjustable vanes that can change the turbocharger’s geometry, optimizing performance across different engine speeds. This technology significantly reduced turbo lag and improved efficiency.

Electronic Control Systems

The integration of electronic control systems in modern turbochargers has revolutionized the way they operate. Electronic controls allow for precise management of boost pressure and air-fuel ratios, enhancing responsiveness and performance. These systems have made turbochargers more efficient and reliable than ever before.

Modern-Day Turbochargers

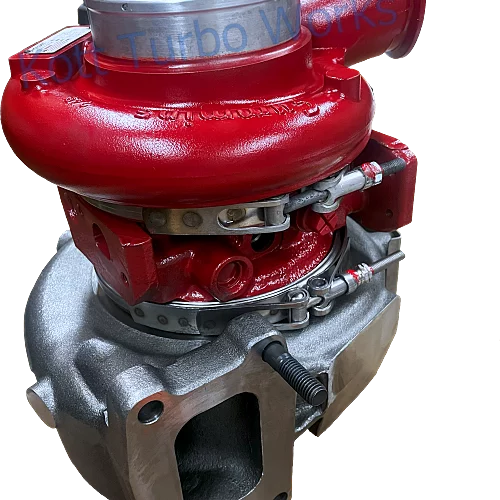

Advanced Materials and Manufacturing Techniques

Today’s turbochargers benefit from advanced materials and manufacturing techniques that improve durability and efficiency. High-strength alloys and ceramics are used to withstand the extreme temperatures and pressures inside the turbocharger. Precision manufacturing ensures that components fit together perfectly, reducing friction and wear.

Hybrid and Electric Turbochargers

The advent of hybrid and electric turbochargers represents the cutting edge of turbocharger technology. Hybrid turbochargers combine traditional mechanical boosting with electric motors to provide instant power and eliminate turbo lag. Electric turbochargers, on the other hand, use electric motors to drive the compressor, offering even greater control and efficiency.

Impact on Heavy-Duty Vehicles

Modern turbochargers have had a significant impact on heavy-duty vehicles, such as trucks and industrial machinery. Turbochargers allow these vehicles to achieve higher power outputs and better fuel efficiency, reducing operating costs and emissions. At Kott Turbo Works, we specialize in turbocharger sales, repair, and remanufacturing for heavy-duty vehicles, ensuring that our clients get the most out of their engines.

Emerging Technologies

The future of turbocharger technology is bright, with several emerging technologies poised to shape the next generation of turbochargers. Advanced aerodynamics, new materials, and innovative cooling solutions are just a few areas where we can expect to see significant advancements. These technologies will continue to push the boundaries of what turbochargers can achieve.

The evolution of turbocharger technology from simple boosters to high-tech marvels is a testament to human ingenuity and innovation. Turbochargers have transformed the automotive industry, providing significant benefits in terms of power, efficiency, and emissions reduction. As we look to the future, the continued advancements in turbo technology promise even greater improvements.

Featured Products

View All

Need Help?

331-888-8726

941-299-1612

Monday – Friday: 9 am-6 pm

Weekend Closed