$0.00

What Causes Turbos to Fail? — Common Causes and Signs a Turbo is Failing

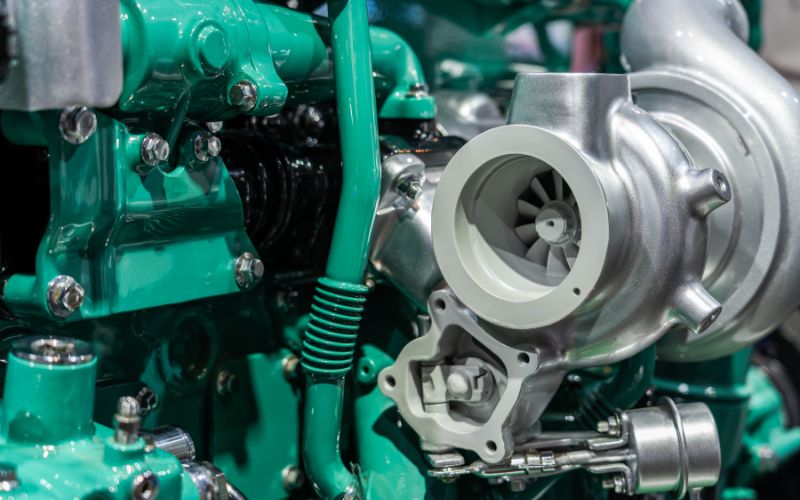

As a distributor of remanufactured turbochargers, we come across many types of damage within turbochargers. Even though we make a living from remanufacturing these components, our customers’ comfort and safety always come first. That is why, today, we present a comprehensive guide to what causes a turbo to fail and how to avoid a turbo failing.

What Causes a Turbo to Fail?

There are many reasons and signs a turbo is failing. Let’s analyze the most important ones below.

Foreign Object Damage

A foreign material may enter the compressor and get sucked in. As a result, such an object can damage the turbo and contribute to turbo failing. Such damages are called impact damages.

Impact damage can be caused by pulling objects into the intake due to the low-quality filter (or an already damaged one). The culprits for the small items entering the intake might also be previously damaged hoses. Similarly, components that break can consequently damage the turbocharger. These are, for example, parts of pistons, valves, or injector nozzles.

One of the most important things to do to prevent turbo failing is to check whether, during servicing, we do not leave such components as washers, bolts, or nuts in the intake pipe. We should also check whether all hoses are in working condition and not blocked. Moreover, old gaskets should always be replaced with new ones to provide a good seal. When it comes to the air filters, make sure your equipment is not worn out. If so, replace it. Before replacing any parts, ensure that no parts of equipment from previous malfunctions remain in the system to avoid another turbo failure.

Oil Contamination

We can expect a turbo failing if the oil filter is blocked or damaged. However, the culprit may also be a high-carbon build-up. Of course, any failures, such as an ill-functioning oil filter bypass valve or engine wear that leaves small parts in the oil, will also contribute to oil contamination. Servicing of the turbo may also accidentally contaminate oil. Finally, too high temperatures can contribute to oil degradation too.

Luckily, turbo failing due to oil contamination can be prevented. Your new turbo fitting must be accompanied by a new oil filter and new oil itself. Before you finish the installation, check whether the inlet pipes are clean or replace them. Otherwise, there might be accumulated carbon that can get into the turbo and cause its failure. Make sure that you use the oil that is appropriate for your engine.

Leakage

Another reason for the turbo failing connected to the oil is its leak. What can contribute to such an occurrence? There are several reasons, such as an intake filter blockage or damage to the air intake pipe or hose. It is also possible that the intake hoses or the intercooler are subjected to an air leak.

Leakage-induced turbo failure can be prevented by inspecting air and drain systems for any blockages or restrictions and ensuring the lack of leakage in the exhaust system.

Oil Starvation

If the oil level in the stump is low or the oil feed pipe is bent and restricting the oil flow, oil starvation may occur. It can also happen when the carbon builds up in the oil feed pipe or inlet gasket gets blocked by applied silicone. Also, the oil inlet gasket itself should be correctly chosen for the type of turbocharger. Otherwise, it might restrict the flow. Oil filters or pumps can also be to blame if they are damaged or blocked. Finally, an often overlooked activity is priming the turbo while conducting its fitting, lack of which also contributes to the issues with oil starvation.

Turbo failing due to oil starvation can be avoided by following a few simple rules. Firstly, avoid applying silicone to oil gaskets as it often causes the blockage of passages. Frequent inspection and cleaning of oil inlet pipes from the accumulated carbon also reduces the risk of potential oil flow restrictions. The oil itself, as well as its pressure, plays a crucial role in the avoidance of turbo failing. Checking the pressure and supply to the component, as well as using new oil and oil filters, are a part of turbocharger maintenance activities.

Overspeeding

Last but not least, overspeeding can also cause your turbo to fail. Many factors can contribute to overspeeding, such as damaged hoses, improper amount of air delivered to the turbo, or an air intake filter with a restriction. Other reasons include broken engine components or injectors, as well as even having improper turbochargers fitted. Wastegate alterations are also a frequent reason for malfunctioning turbos.

To prevent overspeeding and subsequent turbo failure, we must take a few precautions. Firstly, inspect the air intake in search of leakage or restrictions. Furthermore, we must ensure the proper operation of the electronic sensors and ECU, as well as the free operation of VNT linkage and wastegate.

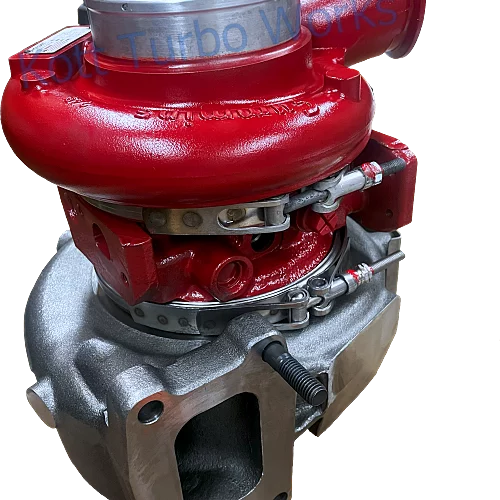

Sometimes, it is too late to catch or properly read the signs a turbo is failing. However, you can always count on our professional advice when it comes to helping you assess the state of your component. Furthermore, if the damage to your turbo is severe or beyond repair, you can choose a more affordable option than buying a brand-new component. Purchase one of our remanufactured turbochargers and enjoy the good functionality and durability of your component.

Featured Products

View All

Need Help?

331-888-8726

941-299-1612

Monday – Friday: 9 am-6 pm

Weekend Closed