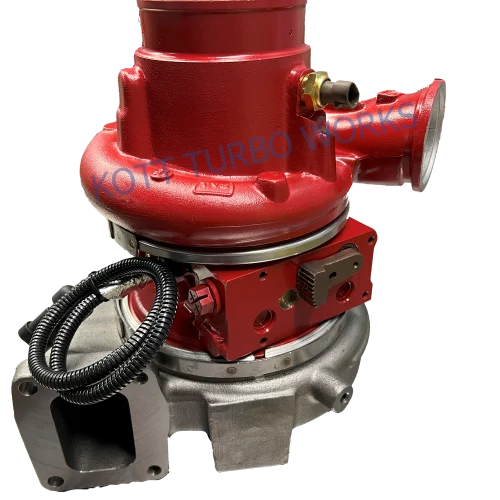

Description

PART NUMBER: 2842125

INTERCHANGE PART NUMBERS:1831156, 1944763, 1944763PEX, 1944763PEX,, 1975197, 2049933, 2049933PEX, 2052194, 2117933, 2842125, 3767294, 3791941, 4031052, 5355096

WEIGHT: 65lbs

CORE CHARGE: $500

ELECTRONIC ACTUATOR – NOT INCLUDED. (Can be purchased separately and calibrated with turbocharger)

GASKET SET – INCLUDED

SPEED SENSOR – INCLUDED

TEMPERATURE SENSOR – INCLUDED

HIGH-SPEED BALANCING (VSR) – PERFORMED

OIL LEAK TEST – PERFORMED

COMPRESSOR INDUCER/EXDUCER DIAMETER: OEM

TURBINE INDUCER/EXDUCER DIAMETER: OEM

Remanufactured in USA by Kott Turbo Works

Turbocharger Remanufacturing Explained

- Stripping down into individual parts – worn-out components are discarded as well as the parts that are still functioning properly but may fail if reused

- Cleaning – reused parts undergo a thorough cleaning process with the use of appropriate chemicals

- Measurements and inspections – all components must meet the strict OEM standards. That is why every part is thoroughly measured and examined.

- Reassembly – all parts are put back together and thoroughly tested to determine whether the turbo can work at its optimum. Extensive checks performed at every stage of the remanufacturing process result in the best performance reliability, and lifespan.

Once all procedures are performed and all components perform up to standards, the turbo is ready.

Our turbochargers have been engineered with great precision. Our expert knowledge and skills allowed us to perform a high-quality turbo repair. The repair was also supported with the use of specialist, highly advanced measuring and balancing equipment. All these elements ensure that the turbochargers lasts as long as the new unit.

All turbochargers have been completely disassembled, cleaned, and inspected for any signs of wear and damage. All improperly functioning components have been replaced with new ones. Our remanufactured turbochargers are nearly indistinguishable from a new part.

Thanks to our modern cleaning equipment, you can be sure that the part you receive is adequately prepared and assembled within OEM specification tolerances. Parts for remanufacturing are provided by UK supplier who specializes in the production of parts according to the same principles as most recognized brands.

Last but not least, the performance of a remanufactured part is identical to an authentic turbocharger. It is assured by thorough checks performed at every stage of the remanufacturing process. As a result, our Clients receive remanufactured turbo providing performance, reliability, and lifespan of a new component.

Also, check out our other options and get the best deals. At Kott Turbo Works you can shop with confidence that your new purchase will be a high-quality remanufactured part.

Warranty policy

All products are backed by unlimited mileage and one (1) Year, Limited Warranty. Please read terms and conditions for full description.

Before fitting the new part, you MUST find the reason why turbocharger FAILED and CORRECT it. Fitting a new turbo will only result the same failure. Less than 10% of turbocharger failures, are due to the turbo itself, in most cases failures are caused by outside influence. Most common causes of consequential failure (NOT COVERED BY WARRANTY) are listed below. All new Kott Turbo Works products are backed by a one (1) Year Limited Warranty. The one (1) Year Limited Warranty covers all manufacturer defects. Warranty does not cover labor recovery, accommodation, or any other costs. Turbochargers must be returned for a detailed warranty inspection. Any modification to the product voids the one (1) Year Limited Warranty. The one (1) Year Limited Warranty does not cover :

- Failure to provide installation documents from repair facility. (Self/parking lot installs)

- Failure to perform and document scheduled maintenance on time.

- Seaping/leaking oil out of compression outlet, caused by excesive BLOW BY or clogged crankcase FILTER.

- Failures due to Improper installation or maintenance, restricted oil feed pipe, damaged oil pump, low oil level, metal particles or carbon present, faulty DPF filters and/or EGR valves, contaminated lubricant, oil starvation.

- Using liquid gasket or sealing compounds

- White deposit present on exhaust parts due to excessive engine oil burn.

- Over speeding, defective intercooler and or compression piping, stuck VGT, Remap

- Foreign object and physical damage, defective or dirty air filter and supply pipes.

Due to the intricacies involved in warranty process and the industry standard protocol regarding the inspection of parts and turnaround time, we will not offer free replacements prior to full inspection and analysis. To minimize potential downtime for our customers, we strongly recommend the purchase of replacement parts as a proactive measure. We kindly request your understanding in this matter.

Core return

Cores must be returned in undamaged shipping conditions, if damage occurs during shipping, due to poor packaging or other reasons we reserve the right to prorate or forfeit core refund at our discretion.

Cores must be returned within 60 days for full core refund and it has to meet all criteria, after that core refund will be at KTW discretion. Upon receiving your good core, we will issue a refund within a 1 week period. All cores are subject to inspection upon arrival. Any returned item with physical damage will result in denial of return credit or refund. The Following are examples of Turbos that will NOT be refunded:

- Turbochargers: Bent or broken anything except turbine shaft. Bent, broken or damaged housing.

- Core has to be sent with copy of purchase order, in order to know for which turbo we have to issue the refund, KTW won’t know who returned it, without proper documentation.

- Core must be like-for-like.

We provide free return shipping using a FREE FedEx return label to return the core back to us, from most of the locations in the US (excluding Alaska, Hawaii, and Puerto Rico).

Shipping and returns

We use FedEx ground for shipping, contact us for expedited service, or other special arrangements.

We usually ship the same day, unless item is out of stock due to local in store purchase, you can call/text us at 331-888-8726 to check availability and place 12 hours hold status on item.

If your order has shipped, the return and restocking fee is 20%. Customer must pay for return shipping. Shipping from when the product was sent out is not refunded as that cost has been spent and is unrecoverable. Returns are only allowed for 14 days from post marked day, after that only store credit can be allowed at our discretion, not guaranteed.

Installation tips

Most common misdiagnosis.

Oil leaks can be caused by a variety of factors, the main factor being incorrect pressure within the compressor and turbine housings, which is usually caused by:

- Blockages to the air intake filter and/or hoses.

- Excessive crank case pressure (blow-by from worn piston rings/bores)

- Blockages in the exhaust system

- Repeated hot engine shutdowns leading to carbon deposits (coke) in the centre housing

- Dirty crankcase filter

- Use of silicon sealant / incorrect gasket, twisted, bent or trapped oil return pipe

Most common turbocharger failure causes on semi trucks:

- Foreign object damage – Broken off engine components, e.g. valves (D13), fragments of damaged pistons or injector tips, EGR block off plates.

- Oil contamination – High carbon build up present in the engine can quickly contaminate new oil, contamination of new oil while servicing.

- Degrading oil – excessive temperatures or extended service intervals.

- Internal engine leaks – fuel or coolant mixing with oil supply.

- Turbocharger overspeeding – Engine modifications including ‘chipping’ or ‘over-fuelling, bad program installed if EGR/DPF delete was performed, worn injectors. Tear in the air hose or the hose becoming completely detached. Restrictions in the air intake filter or pipe work. Air leaks between compressor and engine.

- Lack of lubrication –

-

- Engine left idle for long periods, especially during cold weather

- Oil feed pipes containing bends or kinks

- Lack of maintenance, oil change intervals should be shortened as engine gets old.

- Insufficient oil in the sump

- Incorrect oil inlet gasket used leading to restriction in oil supply

- Build-up (coking) / carbon deposits in the oil feed pipe

- Applying silicone to the oil inlet gasket causing blockages

- Sludge or coke build up in bearing housing from hot shutdowns

- Failure to prime the turbo with oil before initial run

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.