$0.00

Understanding Turbo Lag and How to Minimize It

One common challenge associated with turbocharged engines is turbo lag—the delay between pressing the accelerator and feeling the surge of power from the turbocharger. In this article, we will delve into the intricacies of turbo lag, explore its causes, and discuss effective strategies to minimize its impact on your driving experience.

What Is Turbo Lag?

Definition and Significance

Turbo lag refers to the time delay experienced in a turbocharged engine between the moment the driver presses the accelerator pedal and when the engine delivers increased power. This phenomenon can be frustrating for drivers, especially in situations requiring immediate acceleration, such as merging onto highways or overtaking slower vehicles.

The Mechanics Behind Turbo Lag

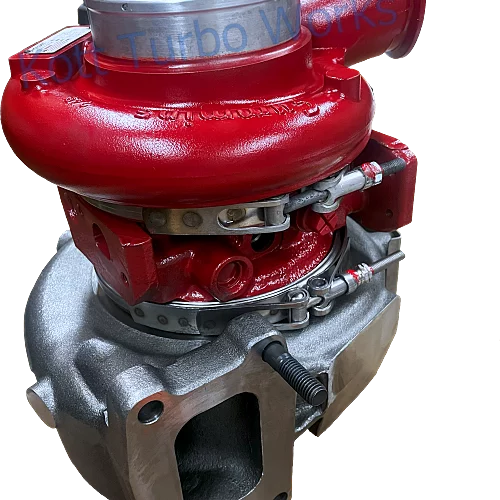

The essence of turbo lag lies in the mechanics of how a turbocharger operates. A turbocharger is a device that uses exhaust gases to spin a turbine, which in turn compresses air entering the engine. This process increases the amount of air available for combustion, leading to more power output.

However, there is an inherent delay as exhaust gases must build up sufficient pressure to activate the turbine. This delay can vary based on several factors, including engine design, driving conditions, and even the driver’s habits.

Factors Contributing to Turbo Lag

Exhaust Gas Pressure Build-Up Time

The primary cause of turbo lag is the time it takes for exhaust gases to build enough pressure to spin the turbine effectively. When you accelerate, there is an initial delay as exhaust gases flow through the system and reach the turbine. This delay can be exacerbated by various factors related to engine design and driving conditions.

Engine RPM Range

Turbo lag is particularly noticeable at low RPMs when there is less momentum available for the turbocharger to spool up quickly. In these situations, drivers may feel a momentary lack of power before experiencing the surge associated with boost. As RPMs increase, however, so does turbine speed, leading to quicker response times.

Design Limitations

Inherent design limitations can also affect responsiveness. The inertia of rotating parts within the turbocharger system can slow down spool-up times. Additionally, intake plumbing losses—where air must travel through various components before reaching the engine—can contribute to delays in achieving optimal boost levels.

Modern Solutions to Minimize Turbo Lag

Lighter Materials

One of the most effective ways manufacturers are addressing turbo lag is through advancements in materials technology. Using lighter alloys and composites reduces inertia within the turbocharger system, allowing for quicker spool-up times and improved responsiveness.

Component Design Improvements

Modern engineering has led to significant improvements in component design. Manufacturers are focusing on reducing friction within bearings and optimizing airflow through better geometries. These enhancements lead to more efficient operation and reduced lag.

Assisted Turbocharging Techniques

Electric Motors

Some manufacturers are now incorporating electric motors into their turbocharging systems. These motors can help spin up the turbine at low RPMs, effectively eliminating lag during initial acceleration phases.

Additional Compressors

In some setups, additional compressors or forced induction devices work alongside traditional turbos. These systems can provide immediate power delivery while waiting for larger turbos to spool up.

Multi-Stage Turbo Setups

Multi-stage setups utilize multiple smaller turbos that operate at different RPM ranges. Smaller turbos can provide quicker response times at lower speeds while larger ones take over at higher speeds for maximum power output.

Practical Methods to Reduce Turbo Lag

Turbo Size Optimization

Choosing an appropriately sized turbocharger is crucial for minimizing lag. Smaller turbos tend to spool up faster but may sacrifice ultimate power output compared to larger counterparts. A balance must be struck based on driving preferences and intended use.

Twin-Turbo Systems

Twin-turbo systems can also help reduce overall lag by employing either sequential or parallel configurations. In sequential setups, one smaller turbo operates at low RPMs while a larger one kicks in at higher speeds. Parallel configurations allow both turbos to work together across various RPM ranges.

Anti-Lag Systems

Anti-lag systems (ALS) are innovative solutions designed specifically to mitigate turbo lag issues. These systems often use superchargers or other technologies that maintain boost pressure even when throttle input is low or during gear shifts. While effective, they may introduce additional complexity and potential wear on components.

Common Issues That Increase Turbo Lag

Faulty Components

Maintaining your vehicle’s health is essential for minimizing turbo lag. Exhaust leaks or boost leaks can significantly hinder performance by allowing air or exhaust gases to escape before reaching their intended destinations. Additionally, faulty wastegates or malfunctioning boost solenoids can disrupt proper boost levels.

Lean Air-Fuel Ratios

A lean air-fuel mixture—where there’s too much air relative to fuel—can lead to inefficient combustion cycles and increased lag. Ensuring your engine runs at optimal ratios is crucial for maintaining performance and responsiveness.

Excessive Engine Wear

Over time, wear and tear on engine components can lead to increased lag due to inefficient operation. Regular maintenance—including oil changes, filter replacements, and inspections—can help keep your engine running smoothly and minimize any potential issues related to turbo lag.

Final Thoughts

Turbo lag may be an inherent characteristic of turbocharged engines; however, understanding its mechanics empowers drivers with knowledge about how best to mitigate its effects. Whether you’re considering a new vehicle or investigating how to enhance your current setup, being informed about turbo lag will undoubtedly lead you toward making better choices that align with your performance goals.

In summary, embracing both technological advancements and practical maintenance strategies will ensure that you enjoy all the benefits of a turbocharged engine while minimizing any drawbacks associated with turbo lag.

Featured Products

View All

Need Help?

331-888-8726

941-299-1612

Monday – Friday: 9 am-6 pm

Weekend Closed